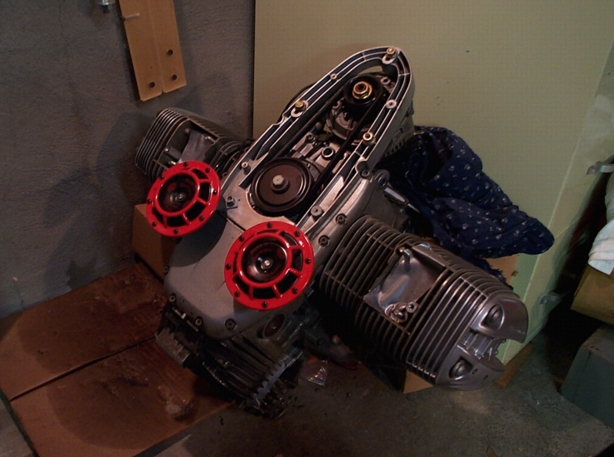

I'll spare you the details of designing and constructing the bracket. It should work just fine, I'll mount it to the smaller hole on the boss at the bottom of the timing cover. That hole takes an 8x1.25 mm tap just fine, and the bracket will be supported on its sides against the insides of the timing cover.

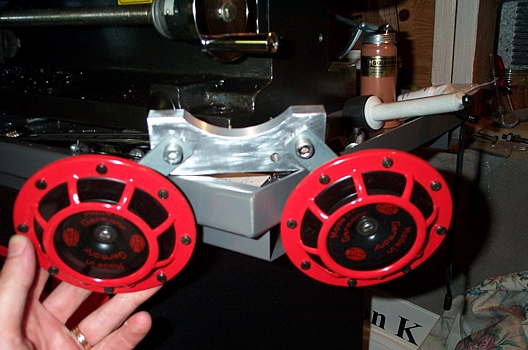

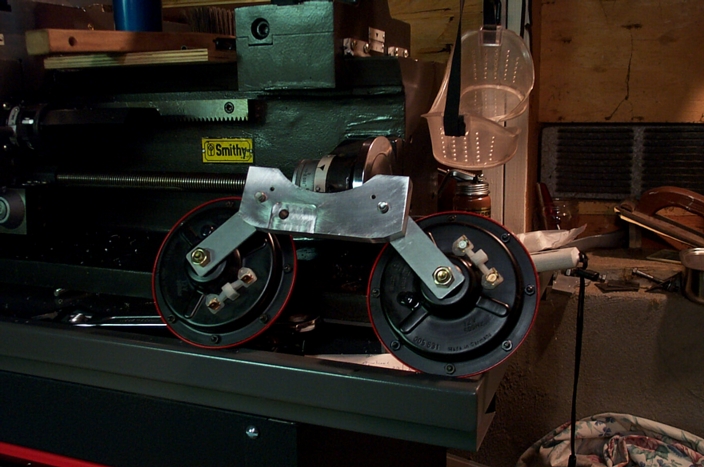

Why go to all the bother of milling a piece of aluminum for this? I'll admit, I was looking for a first project on the new Smithy lathe/mill combo, and this was all good practice. I'll put up more pictures when the horns are mounted on the bike.

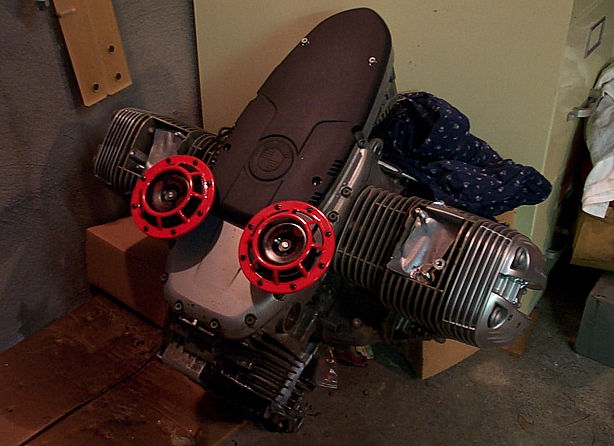

What they look like with the timing cover in place.

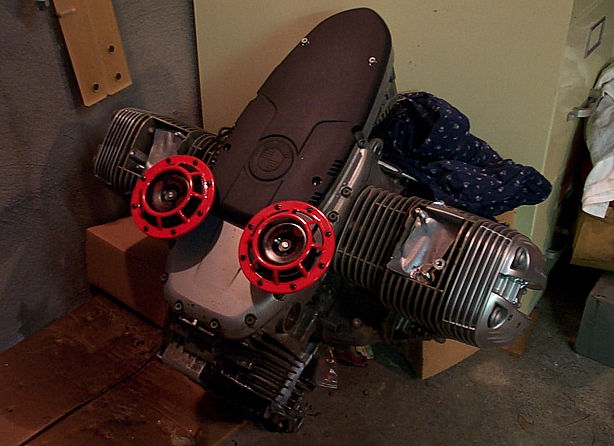

And with the timing cover removed.

This shows the boss with two holes at the bottom below the pulley.

Front view.

Rear view, with relief for sitting on top of the boss.

Three stainless 8x1.25 mm bolts, the bracket and the horns. The bracket is tapped for the two horn bolts, the mounting hole has clearance for the 8 mm bolt.

It helped to have a spare engine for taking measurements! The jealous R80 will be keeping its dual FIAMMs.