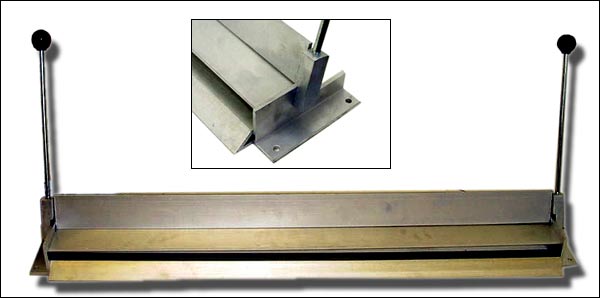

Long bends for Scratch Builders of sheet metal airplanes

You may recall I was working on an "Amateur Folder" per Michel Columban, the French designer of the Cri-Cri. But I was stretching the limits, again. I need to bend stuff up to about 4 feet long, at least, substantially longer than the Prototype was designed for. To make a LONG story short, it didn't work when bending the 2219-T8 I have in abundance. So, I'd noticed what looked like a suitable brake on E-Bay, and I threw money at the problem.

My heart fell when it was delivered - it's all out of aluminum. The forces involved in bending build up pretty quickly, and even though it was advertised is being capable of bending "14 gauge metal" (? steel? Aluminum? Copper? - 14 gauge's about .080", depending on the metal), it too failed at bending a mere .020" 2219-T8 about 2-1/2 feet long. The bending leaf visibly deflected as soon as I put some muscle into it. I can't recommend anyone buy one of these. Maybe if I was using 2024-T3, like I should be it would work, but I'm skeptical it's good for anything other than mild steel, annealed, or dead soft aluminum.

So, I need to send the damn thing back, and get it out of my shop, even though it's not clear the Seller will refund my money, and there is NO way I'm getting my shipping charges back. How to box it up so that it will get to South El Monte? I threw the original box away as soon as I opened it up, well before I actually tried it out - Doh!

Well, since I've got plenty of .020" 2219-T8....

The end caps are particle board scavenged from discarded IKEA furniture discarded by apartment dwellers in my neighborhood. A few sheet metal screws hold them in. The top is held on with 600 MPH tape and the aforementioned sheet metal screws at the ends.

The main body is a channel I bent using a technique I learned from Dave Thatcher, the CX4 guy, and therein lies the bulk of this tale. I got a DVD of him from another builder bending up an aileron at Sun and Fun using little more than a forum-issue folding table, a 2 X 4, a rubber mallet, and the real secret, a piece of 1/4" plywood.

I'd bent stuff by clamping it and hammering it before, but in thin aluminum, I've never been pleased with the "free" edge of the resulting part. The mallet blows stretch the metal rather unevenly, leading to a lot of ripple. Not much of a problem when a channel spar is riveted to a skin, as in tailfeathers, but a big problem for longerons, as used in the tailcone of various Hummel avias.

Let me cut to the chase: using a piece of plywood to distribute the blows makes it possible to make incredibly straight bends with bupkus for tooling. You still have to tightly clamp the sheet stock between two fairly rigid bars of something (Dave advocates an 8 ft long section of 3 X 3 inch or bigger STEEL angle, fastened to the front of your bench, level with the top), and you're limited by the throat depth of your C-clamps to how wide a flange you can throw, but I bent up the channel that forms the "box" above in pretty short order. Some pictures:

Notice in this setup, I'm able to clamp from the back. If you're clamping from the front, just periodically use the mallet to swing the clamps from side to side, the get the whole length of the bend uniformly bent. It has to be plywood, solid wood of comparable thickness with split to splinters in 2-3 blows.

Here is Your Author, in his Industrial Jammies (no heat in the shop, it may be California, but 50 degrees and raining hard is still 50 degrees), workin' it. Note: this process is Loud. Girlfriend was wearing my earmuffs while I wailed on this mutha. This is not something you can do late at night in a shop with 6 mil plastic walls.

So, the "failure" of both the "Amateur Bender" and the E-bay Cheap Chinese Junk lead to some learning. I was reluctant to try Dave's technique, and was thinking of building yet another bending device, probably this one from the www.ch601.org website, since it doesn't require any welding. And I still may do, but having tried this technique, on a project that didn't require Flight Hardware, I may not need to. Having a non-critical project to learn on is a really good way to teach yourself the skills you need to build an airplane from scratch, when you can't have a kindly A&P standing at your shoulder at all times, teaching you the ropes he learned from Donald Douglas Senior Back In The Day.

0 Comments:

Post a Comment

<< Home